FIBERCOLL-FLEX® BIOINKS

Discover the ultimate freedom in bioprinting!

FIBERCOLL-FLEX® BIOINKS

Fibrillary collagen bioinks for tissue model printing

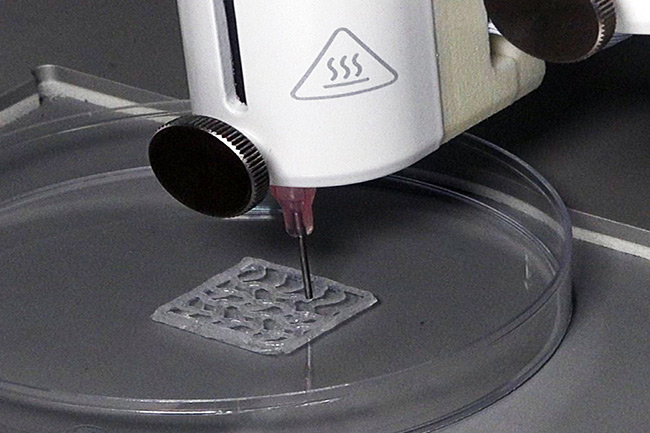

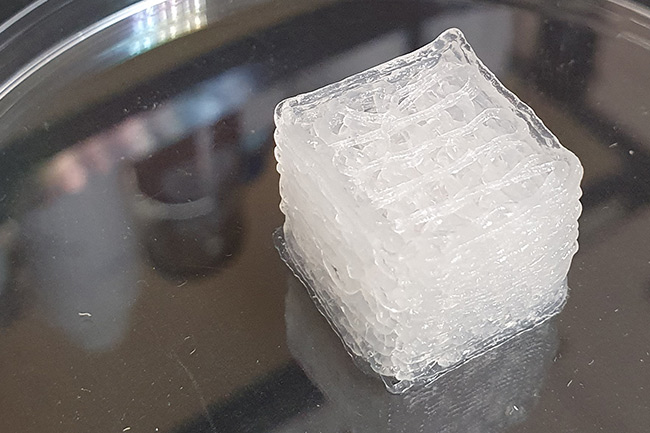

As the only fibrillary collagen bioinks in the market, our Fibercoll-Flex® products consist of pure type I collagen fibers with high mechanical strength that enable easy printing without a methacrylation curing step. The stable 3D models are highly biocompatible and represent in vivo like scaffolds for cell adherence & remodeling, widely applicable in tissue engineering or regenerative medicine research and development.

A publication by Garcia-Villen et al. (2023) demonstrates and summarizes the advantages of the new bioinks for 3D printing & bioprinting.

Fibercoll-Flex-N®

Easy 3D model printing with encapsuled cells at physiological conditions

Made of acidic collagen fibers, the Fibercoll-Flex-N® is neutralized before printing, enabling the generation of bioprints with encapsuled cells at physiological conditions. The self-supporting 3D models with high shape fidelity and proven biocompatibility can be immediately handled and cultured after printing. The native fibrillary collagen type I represents an excellent in vivo like scaffold that promotes cell performance. Tunable stiffness between 0.2 – 0.9 kPa.

Fibercoll-Flex-A®

Robust 3D scaffolds with optimal mechanical properties

The acidic Fibercoll-Flex-A® bioink enables the printing of solid forms with exceptional shape fidelity at a higher stiffness range than the Fibercoll-Flex-N®. 3D models are neutralized after printing and cells seeded on top of the scaffold. The native fibrillary collagen type I represents an excellent in vivo like scaffold that promotes cell performance. Tunable stiffness between 2 – 10 kPa.

BENEFITS

- Pure & native type I collagen fibers

- No curing step

- Easy stiffness regulation

- High print fidelity & excellent biomechanical properties

- Suitable for composite inks

- High biocompatibility & authentic cell performance

-

Broad range of applications in regenerative medicine

& tissue engineering

APPLICATIONS

The technical specifications of our Fibercoll-Flex® bioinks and the ease of use enable novel & flexible solutions in bioprinting of 3D models, such as

- Complex tissues

- 3D tumor models

- Substitute for animal models

- Cell based assays for screening

- 3D scaffolds for biomedical research

Quality

- Ultrapure collagen type I fibers

- Average fiber length 200 – 800 µm with diameter of ~20 µm

- Produced under ISO 9001 quality management

- Available in research grade

| Cat. No. | Description |

|---|---|

| 500069016 | Fibercoll-Flex-N®, 3 mL hydrogel in syringe |

| 500069011 | Fibercoll-Flex-A®, 3 mL hydrogel in syringe |

Our Fibercoll-Flex® bioinks are delivered as 3 mL unit in an individually packed syringe.

order information

Available worldwide through REGEMAT 3D

phone +34 685 489097

info@regemat3d.com

Available in the USA through VWR

For special needs please contact:

James Murray

Biomedical Business Manager

Viscofan BioEngineering / Viscofan USA Inc.

MurrayJ@usa.viscofan.com