BIOPRINTING

BIOPRINTING

Discover the ultimate freedom in bioprinting!

The printing of 3D models is a rapidly growing field with a broad range of applications in tissue engineering, regenerative medicine, transplantation and clinics, drug screening, high-throughput assays or cancer research. The technical challenge is to generate models that resemble natural tissues by using advanced biomaterials in combination with living cells.

With Fibercoll-Flex® Viscofan BioEngineering has revolutionized the field by developing the only two fibrillary collagen bioinks in the market. Both products consist of pure type I collagen fibers with high mechanical strength that enable easy printing without a methacrylation curing step. The stable 3D models are highly biocompatible and represent in vivo like scaffolds for cell adherence & remodeling in tissue engineering or regenerative medicine.

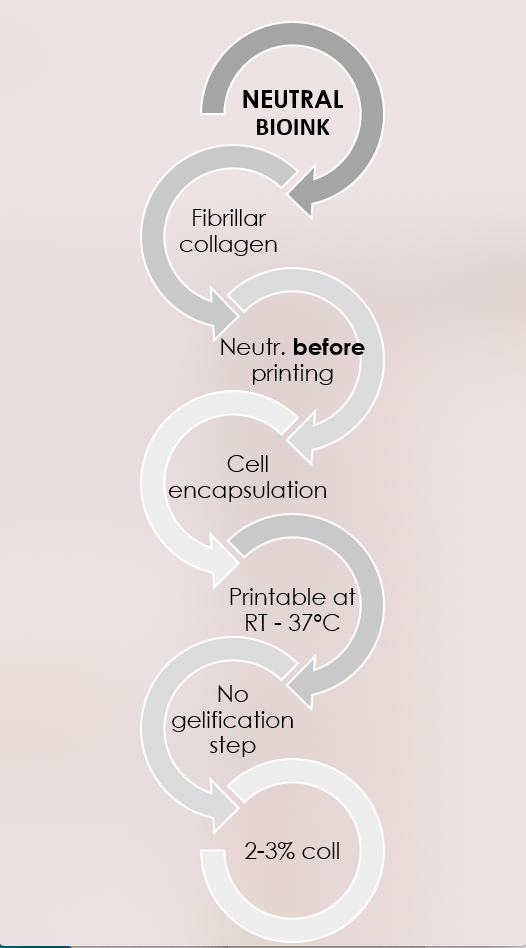

Relating to our clients’ needs, we have generated Fibercoll-Flex-N®, a neutral bioink that enables bioprinting with encapsuled cells at physiological conditions and Fibercoll-Flex-A®, an acidic bioink with higher stiffness range that serves as a robust scaffold with cells seeded on top.

Easy 3D model generation with Fibercoll-Flex® bioinks

At Viscofan BioEngineering, we are always testing new applications for our products and are proud to introduce our latest innovation in 3D bioprinting: a collagen-hydroxyapatite composite bioink that brings us closer to replicating native bone tissue.

What’s new?

We’ve combined our high-strength fibrillar collagen bioink Fibercoll-Flex-N® with tunable concentrations of microparticulate hydroxyapatite (HAp) to create a bioactive, printable scaffold that mimics the mechanical and structural complexity of bone.

Why it matters:

Regenerating functional bone tissue requires more than just biocompatibility—it demands mechanical resilience, shape fidelity, and osteogenic potential.

Our composite:

- Offers tunable mechanical properties

- Supports 3D bioprinting of anatomically accurate grafts

- Enhances osteogenic differentiation

- Shows high cell viability and proliferation

The composite bioink is ideal for developing in vitro bone models or translating regenerative strategies for complex defects and we have confirmed that this platform delivers robust, reproducible performance.

APPLICATION IN EU RESEARCH PROJECT TRIANKLE

TriAnkle – A regenerative therapy for ankle injuries based on collagen bioprints

TriAnkle is collaborative research project with 12 partners from 5 countries, funded from the European Union’s Horizon 2020 research and innovation framework program. Viscofan BioEngineering takes the lead as coordinator and is also providing collagen materials to the project at the frontier of biomedical science.

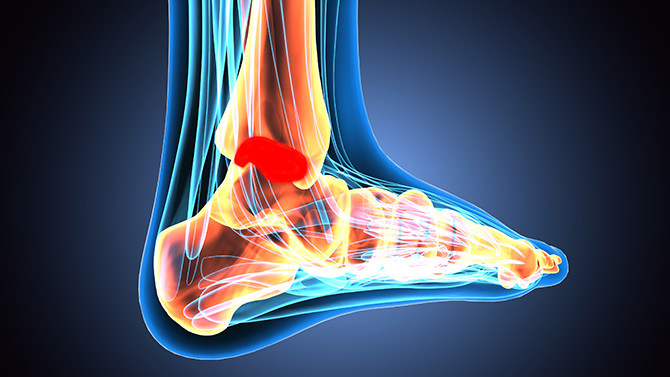

Goal: To develop innovative personalized collagen- and gelatine-based implants manufactured with 3D technology for patients suffering from osteoarticular diseases. In particular, finding a suitable therapy for tendon, ligament and cartilage regeneration.

Main objective: Reduce recovery time down to 50% and increase the functionality ratios up to 10-15%.

Scope: Implementation of case studies for osteochondral cartilage injuries and partial rupture (>50%) of Achilles tendon.

Research focus: Development of 3D printing technologies for innovative personalized collagen based tendon or cartilage implants.

Budget & time line: The ambitious research project in regenerative medicine comes with an overall budget of €5.9M and will be developed over 4 years (2021-2025).

Demonstrating TriAnkle progress in regenerative therapy development

In the past five years, collaborators of TriAnkle across Europe have used collagen- and gelatine-based scaffolds to induce a better and faster regeneration of damaged joint tissues. Coordinated by Viscofan BioEngineering, they are now a step closer to manufacturing personalised implants using 3D bioprinting technologies for patients suffering from osteoarticular diseases.

The magnitude, the impact and the progress of this prestigious EU project is documented in a TriAnkle video series:

Pushing the frontiers of implant printing together with CELLINK

CELLINK is one of the TriAnkle partners that contributes to the project by developing biocompatible articular cartilage scaffolds based on an extrusion-based 3D bioprinting technology. The personalized scaffolds can be tailored to each individual injury’s geometrical characteristics and mimic the biomechanical properties and structure of joint tissues such as ligaments and tendons.